1. Waste acid cracking technology

Waste sulfuric acid cracking technology

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Due to the wide range of uses of sulfuric acid, many industries apply sulfuric acid. Most of the half sulfuric acid is used to decompose phosphate rock to produce phosphate fertilizer, and the calcium sulfate produced is either applied to the soil together with fertilizer (such as superphosphate) or stored as waste. Only a small amount of phosphogypsum is utilized to produce sulfuric acid. Most of the sulfuric acid consumed in other industries is used only as a reaction medium and does not enter the final product, causing a much greater problem than the phosphate fertilizer industry. Most of them are diluted to different concentrations and contain more or less various impurities. The content of impurities depends on its use, from a small amount of volatile organic compounds to a large amount of heavy organic or inorganic impurities. Usually called waste acid. With the development of production, the number and types of waste acid are increasing. The requirements of environmental protection are increasingly strict, and the treatment of waste acid has been mentioned in an important position.

The recovery method of waste acid needs to be determined according to the concentration and impurity content. Waste acid with a low impurity content can be directly used in industrial production, for example for the manufacture of superphosphate. Low concentration can be concentrated by the way of concentration. Waste acid with high impurity content must be treated in a complicated way or completely decomposed to produce sulfuric acid again. The method of complete decomposition is called waste acid cracking. In this kind of waste acid, the largest amount is titanium dioxide waste acid, methyl methacrylate (organic glass) waste acid and petroleum alkylation waste acid.

The impurities in waste sulfuric acid may contain nitric acid, nitrates, chlorine, fluorine, sodium, zinc, copper, ferrous iron, etc., in addition to organic matter and water. The most important impurities are organic matter, nitric acid, nitrate, chlorine, fluorine and sodium. High temperature pyrolysis of organic matter in waste acid. Chloride-containing waste acid has a wide range of sources, such as chlorine gas drying waste acid, chloral acetaldehyde waste acid, etc. In the incineration process, chlorine will exist in the form of hydrogen chloride or chlorine gas. Chlorine and fluorine are similar in chemical properties and belong to family elements. However, the harm of chlorine in the gas is mainly to produce chlorine corrosion to stainless steel. Therefore, the chlorine content in the waste acid must be strictly controlled. The sodium salt in waste acid mainly includes sodium sulfate, sodium sulfite, sodium nitrate and sodium sulfonate, etc., and the source is very wide. In the incineration process, the sodium salt hardly decomposes, and will exist in molten form at high temperature, which is easy to adhere to the waste heat boiler pipe. Sodium salt in waste acid is also an indicator that needs to be strictly controlled.

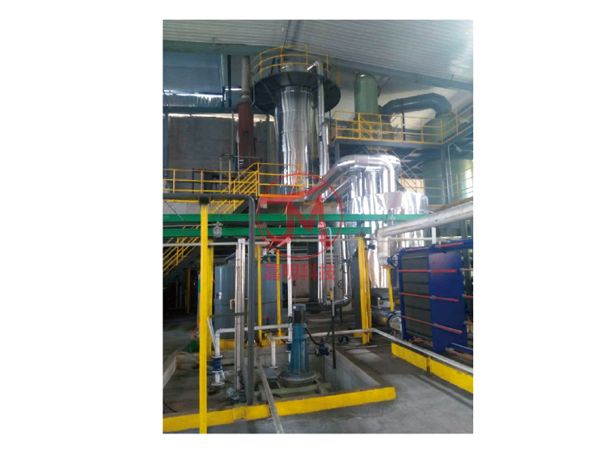

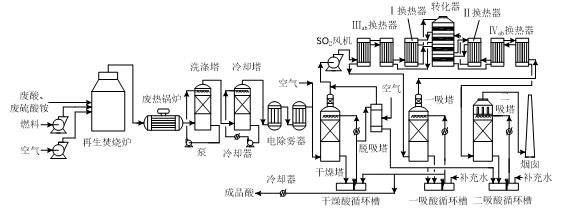

The waste acid recovery unit mainly includes waste acid decomposition process, gas purification process, conversion dry absorption process, waste heat recovery process and DCS system. A typical high-temperature reductive decomposition process is initially used for the regeneration of alkylation waste acid, and then used for the treatment of waste acid containing various organic impurities and ammonium salts. The process does not use any reducing agent, heavy oil or natural gas as fuel, in the decomposition furnace 1000~1100 ℃ sulfuric acid decomposition into SO2, waste acid in the organic matter is completely decomposed, SO2 gas after pretreatment sent to the acid plant to produce sulfuric acid.

Typical high temperature reduction decomposition process flow chart

Key words:

1. Waste acid cracking technology

Pre

Pre

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.