7. Liquid sulfur trioxide production technology

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

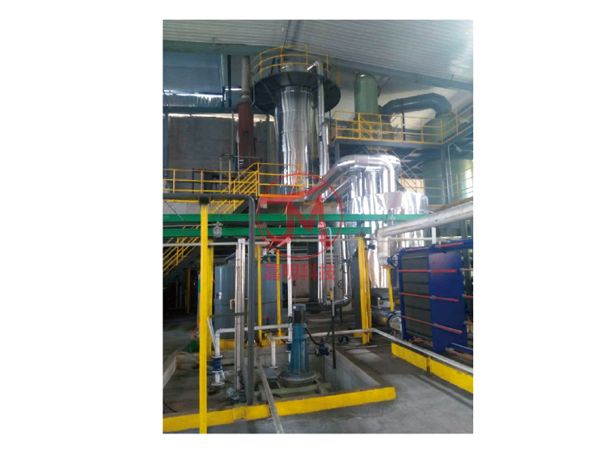

The conversion system is the abbreviation for converting sulfur dioxide into sulfur trioxide. It consists of a heat exchanger group and a converter. The converter is equipped with a multi-layer vanadium pentoxide catalyst. Sulfur dioxide reacts with oxygen on the surface of the catalyst to become sulfur trioxide. The heat generated by the reaction is exchanged by a heat exchanger. According to different requirements, there is usually one transformation and two transformations, mainly two transformations.

After defoaming by the wire mesh demister of the drying tower,SO2 concentration is~8.5%After the furnace gas enters the sulfur dioxide blower to boost the pressure, it passes through the firstIIIHeat Exchanger and No.IHeat exchanger~ 430 ℃, into the converter. The first conversion was reacted by one and 2. three catalyst layers respectively andI,II,IIIHeat exchanger heat exchange, conversion rate reached95.5%, the furnace gas after reaction heat exchange is cooled by the economizer180℃, into the first absorption tower absorptionSO3After that, they passed through the firstIVand No.IIAfter heat exchange, into the converter four for the second conversion, the total conversion rate reached.99.75%Above, the secondary conversion gas passes through No.IVAfter the heat exchanger exchanges heat, the temperature drops156℃into the second absorption tower for absorptionSO3. In order to adjust the inlet temperature of each catalyst layer, necessary secondary lines and valves are set. In order to facilitate the heating and preheating of the system, two electric furnaces are installed at the inlet of the first and fourth sections of the converter.

Sulfuric acid equipmentMain features of conversion section:

(1) In order to improve the total conversion rate and reduce exhaust emissionsS02volume, improve the utilization rate of sulfur in flue gas, application3 1Double contact conversion, conversion flue gas heat exchange process is used.Ⅲ I-ⅥIIProcess.

(2) The heat exchanger adopts a hollow shell-and-tube heat exchanger, which has a higher heat transfer coefficient and lower resistance drop than the traditional single-circle baffle heat exchanger.

(3) Conversion process production and shutdown maintenance The heated air is recycled by using the hot flue gas at the outlet of the second absorption tower, and a part of the waste heat is used to save fuel.

(4) In the piping design of the transformation section, expansion joints, supports, different pipe supports and pull rod structures are arranged in different parts according to different situations, so that the equipment pipeline is compact, the pipeline system has good elasticity, and there is no air leakage due to thermal expansion and cold contraction.

(5) The catalyst is filled in the converter to ensure thatS02The conversion rate of sulfur dioxide should be controlled99.8%Above, the introduction of low temperature vanadium catalyst from abroad.

(6) Desinerated water and power plantThe desalination unit adopts primary desalination system. The desalted water output is15t/h. The desalted water process is: raw water→Raw water tank→Raw water pump→Mechanical filter→counter-current regenerative cation exchanger→Carbon dioxide removal device→Intermediate water tank→Intermediate water pump→counter-current regenerative anion exchanger→desalted water tank→Desalting water pump→Deaerator (the deaerator is installed in the powerhouse). Hydrochloric acid and sodium hydroxide solution are used as the regenerant, and the acid-base wastewater is discharged to the sewage treatment station outside the sulfuric acid unit.

The demineralized water is sent to the boiler feed water deaerator and further heated with low pressure steamDeoxygenation is carried out at 105 ℃, pressurized by the boiler feed water pump, and the feed water temperature rises150℃Left and right, and then sent to the steam drum of the waste heat boiler respectively. Another way to feed water supply high-temperature superheater between the two stages of spray desuperheater. The waste heat boiler is a single drum horizontal flushing brick lined water tube boiler, the heating surface is a vertical suspension serpentine structure, the heating surface includes several groups of evaporation zone and high and low temperature superheater. After the feed water is exchanged with the high-temperature furnace gas, saturated steam is produced at the main steam port of the drum, and saturated steam is finally produced through the high and low temperature superheaters.3.82MPa 450 ℃Medium pressure superheated steam14t/h. produced by the boiler3.82MPa 450 ℃Medium pressure steam14t/hIt is delivered to the powerhouse through the main steam pipeline. Since other devices do not have steam requirements, they are used.3000kWCondensating steam generator set,14t/hMedium-pressure superheated steam can generate electricity2941kw.h. The steam for the deaerator is supplied by the steam extraction port of the steam turbine for the deaerator. In order to protect the quality of boiler water and steam, this section is equipped with a set of boiler water dosing device to control water quality.

(7)Process control characteristics The whole sulfuric acid plant mainly adopts distributed control system (DCS) to achieve centralized management, decentralized control. In the system structure, the data acquisition function and control function should be distributed on different modules to effectively disperse the hazards caused by accidents to the whole system.PIDThe parameters shall be able to be set automatically. The system has rich operation control function, logic operation function, high control quality, easy to focus on monitoring and operation, monitoring intuitive and clear, good system diffusion, easy to improve the control scheme, with diagnosis and corresponding protection function, control station hardware redundancy, the overall not less1:10, the important control loop should be1:1, the communication redundancy with the operation station is1:1. Communication rate not less1Mbps. Dynamic element update time≤1Seconds.Sulfuric acid equipmentDCS Control RoomThe internal communication system is fully redundant.Uninterruptible power supply is required for DCS power supply(UPS). Battery capacity30minute to consider.

Key words:

7. Liquid sulfur trioxide production technology

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.