4. Arsenic harvesting technology from flue gas

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Arsenic is the main impurity element in the smelting process of copper, zinc, lead, tin and other non-ferrous metals. The flue gas after smelting contains a large amount of gasified arsenic trioxide, which has a great impact on the subsequent flue gas treatment, and its own pollution is serious. It has been plagued by non-ferrous smelting enterprises.

Removal of Arsenic from Nonferrous Smelting Flue Gas at Present(Recycling)Technology is divided into wet and dry two categories, wet technology generally uses dilute acid multi-stage washing.+The gaseous arsenic in the flue gas enters the liquid phase and is removed from the flue gas. After treatment, the polluted acid containing arsenic and heavy metals is produced. The polluted acid has complex composition, difficult treatment and high cost. The dry process technology is to change the arsenic in the flue gas from gaseous state to solid state and separate it by cooling.

Dry arsenic harvesting technology is now mainly divided into quenching and gradual cooling process. The quenching process is to spray water mist into the hot flue gas to promote the rapid cooling of the flue gas,As2O3At the same time, the crystallization is precipitated, and then the arsenic is collected by cloth bag. The advantages of this method are compact equipment and good cooling effect. However, due to the high moisture content in the flue gas, the dew point temperature is high. This leads to short equipment life and short continuous driving time. At the same time, the cathode plate and anode wire of the electrostatic precipitator are seriously bonded with fine particles, resulting in abnormal operation of the electrostatic precipitator, failure of voltage and secondary current, failure to reach operating parameters, low dust removal efficiency, easy adhesion of arsenic collection bags, high system resistance, low system start-up rate, frequent maintenance, high labor intensity, difficult cleaning of the system and large loss of gold elements. This method is now being phased out.

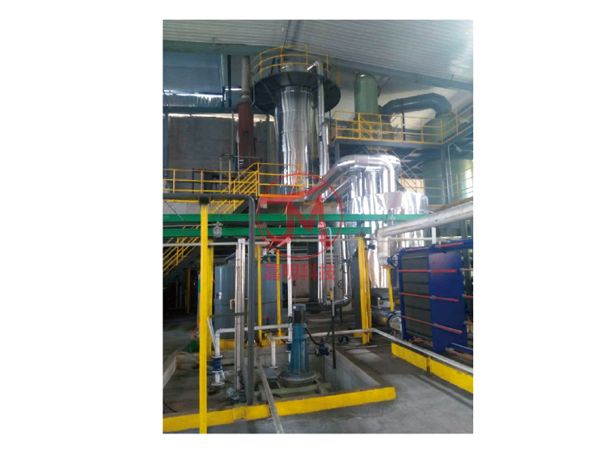

Gradual cooling process is divided into water cooling and air cooling process. The water-cooling process is also being phased out due to the susceptibility to glass arsenic and blockage of equipment. The air-cooling process uses cold air to slowly cool the hot flue gas to avoid the production of glass arsenic. The advantages of this method are reliable system, long continuous driving time and high arsenic removal rate from flue gas. The disadvantage is that the system occupies a larger area and the investment is slightly higher than the quenching method.

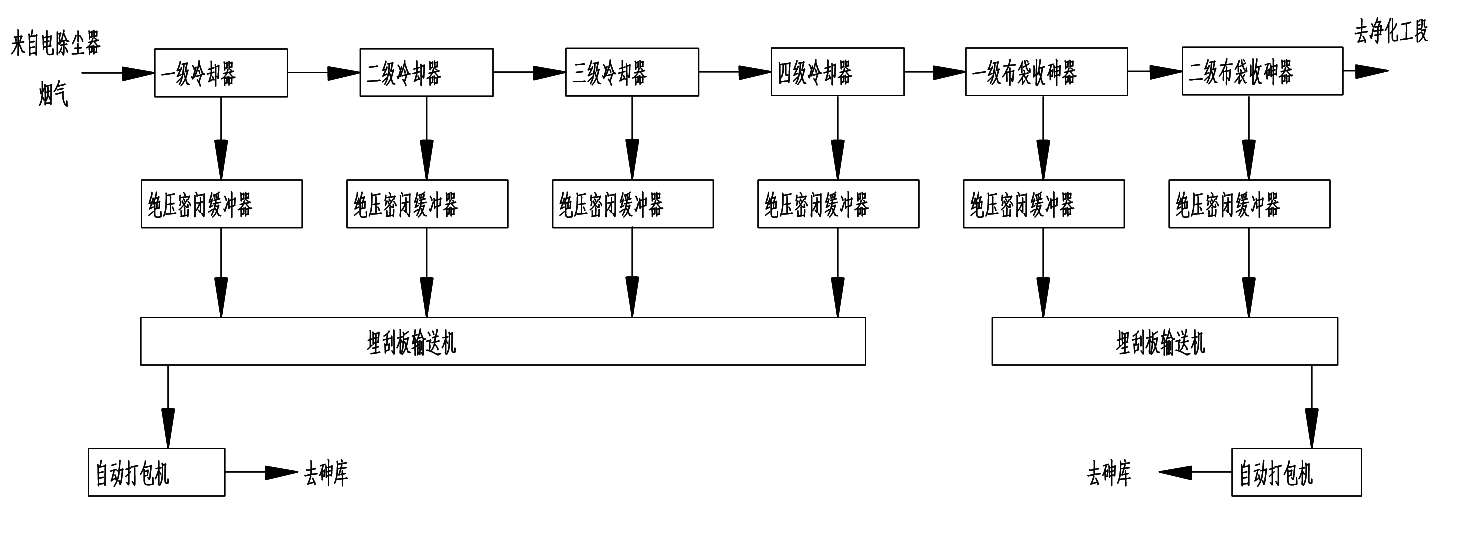

The process flow of dry gradual cooling of arsenic in Yangzhou Jiaming Company is shown in the figure.

Most of the arsenic elements are collected in the bag dust collector, which realizes the harmless and comprehensive utilization of harmful arsenic, and turns waste into treasure. Avoid environmental pollution.

Key words:

4. Arsenic harvesting technology from flue gas

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.