12, coking desulfurization waste liquid multi-component salt technology.

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

During the coking process, a large amount of waste liquid needs to be treated, and desulfurization waste liquid is one of them. The desulfurization waste liquid contains high concentration of sulfate, ammonia nitrogen and other harmful substances, if the direct discharge will cause serious pollution to the environment. Therefore, by extracting the salts therein, not only the discharge of the waste liquid can be reduced, but also the extracted salts can be recycled, which has important economic and environmental significance.

At present, the desulfurization process of large-scale coking plants in China generally adopts ammonia gas desulfurization technology. In the desulfurization process, when the salt content of the desulfurization liquid reaches a certain value, the desulfurization efficiency is significantly reduced, and the desulfurization liquid becomes desulfurization waste liquid. At this time, a part of the desulfurization waste liquid must be discharged, and a new desulfurization liquid must be added at the same time, so that the system can continue to operate normally. The discharged desulfurization waste liquid is generally sprayed on the coal pile as coal blending water, which not only seriously pollutes the environment, but also seriously corrodes the equipment. At the same time, spraying the desulfurization waste liquid on the coal pile seems to solve the problem of desulfurization waste liquid treatment and no waste liquid is discharged, but it does not fundamentally solve the pollution of desulfurization waste liquid. After these coals with desulfurization waste liquid enter the coke oven, they will still be converted into sulfur dioxide, hydrogen sulfide and other sulfides at high temperatures, and eventually return to the desulfurization waste liquid. Moreover, this treatment method of spraying desulfurization waste liquid to coal piles not only affects the quality of coke and pollutes groundwater, but also increases the energy consumption of coking, which seriously restricts the long-term stable operation and sustainable development of coking enterprises.

The salt extraction process from desulfurization waste liquid is to extract ammonium thiosulfate, ammonium sulfate and ammonium thiocyanate from waste liquid by crystallization separation to turn waste into treasure. At the same time, the extracted clear liquid is replenished to pre-desulfurization for recycling. It can not only extract thiocyanate products with high added value from waste liquid, but also solve the pollution problem generated by desulfurization waste liquid in the production process of original desulfurization process.

Process principle of salt extraction from coking desulfurization waste liquid:Thiosulfate is converted into sulfate and sulfur by using the principle that sulfate and sulfur can be generated under catalytic oxidation, and then the solubility of thiocyanate and sulfate is different with temperature, and the separation of sulfate and thiocyanate is achieved by controlling the temperature. Ammonium thiosulfate can be converted into valuable ammonium sulfate products, and the catalyst can be recycled through the regeneration process, so as to realize the comprehensive utilization of all components of desulfurization waste liquid. As a result, the purity of the thiocyanate series products is improved, and the nitrogen content of ammonium sulfate products reaches20%Above, the added value of the product is greatly improved. The catalyst has the advantages of fast catalytic speed, strong pertinence and sulfur conversion. In the process of thiosulfate treatment, the catalyst is very important.

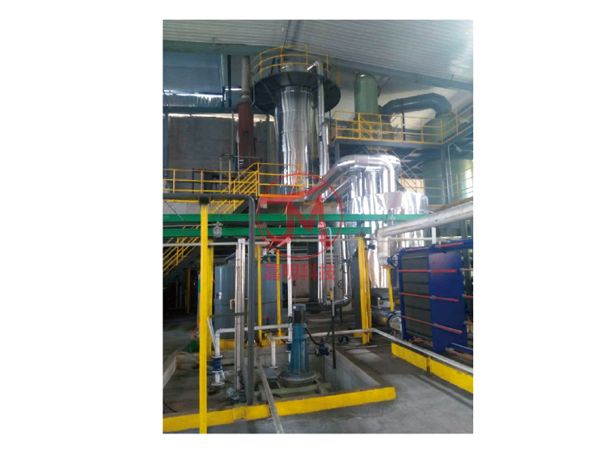

Process flow of salt extraction from coking desulfurization waste liquid:Mainly through the desulfurization waste liquid oxidation, filtration, decolorization, filtration, concentration, adjustment, centrifugation, fine adjustment, fine filtration, crystallization, centrifugal separation, drying, packaging and other more than a dozen steps to complete the extraction of products. Catalytic conversion: a certain amount of catalyst is added to the pretreated desulfurization liquid, treated by heating, stirring, blowing in excess air and other measures, and the sulfur is separated, and the clear liquid enters the clear liquid storage tank for the next process. A certain amount of activated carbon is added to the desulfurization liquid after catalytic conversion, and treated by heating, stirring, filtering and other measures to obtain a qualified clear liquid, and the waste activated carbon is separated, and the clear liquid enters the clear liquid storage tank for the next process. Using the evaporator to concentrate the clear liquid, the evaporator can greatly improve the evaporation efficiency of the desulfurization waste liquid, and at the same time can improve the utilization rate of steam to a greater extent. The filtered concentrated liquid is adjusted, and the adjusted liquid is then subjected to solid-liquid separation by a centrifuge to obtain an ammonium sulfate product.

The technology of salt extraction from desulfurization waste liquid can recover secondary salt from desulfurization waste liquid, which is in line with the national policy of energy conservation and emission reduction and the basic requirements of environmental protection. It can not only make up for the decline of desulfurization efficiency caused by the accumulation of secondary salt in desulfurization liquid and the shortage of environmental pollution caused by dumping waste liquid in the traditional desulfurization process, but also recover a series of chemical products with high added value, which can be said to be both environmental protection and value-added.

Key words:

12, coking desulfurization waste liquid multi-component salt technology.

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.