8. Ionic liquid desulfurization technology

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Ionic liquid desulfurization is a renewable desulfurization technology. The technology has a large flue gas treatment capacity and a large fluctuation range of SO2 concentration in the flue gas. φ(SO2) can be 0.02 to 5%. When the sulfur content in the flue gas is high, the investment and operating costs are more advantageous, and it can be used to treat the waste gas produced by the chemical and metallurgical industries. Ionic liquid desulfurization process not only has high SO2 removal rate, but also can produce high concentration of SO2 gas, which can meet the requirements of environmental protection and realize waste gas resource utilization, and has broad application prospects.

Process principle

Ionic liquid is a kind of organic cations, inorganic anions, adding a small amount of antioxidants and activator of aqueous solution, at a lower temperature to absorb SO2, at a higher temperature to SO2 desorption, desulfurization liquid regeneration, can achieve the purpose of simultaneous removal and recovery of SO2. The desulfurization mechanism is as follows:

SO2 H2O←→ H+ HSO3- (1)

R H+←→ RH+ (2)

Total reaction formula:

SO2 H2O R ←→ RH+ HSO3- (3)

where R represents a complex amine absorbent,Formula (3) is a reversible reaction. Reaction (3) proceeds from left to right at low temperature, and reaction (3) proceeds from right to left at high temperature.

"Technology for the removal and recovery of sulfur dioxide from flue gas by ionic liquid circulation absorption", usingAbsorbent vapor pressure is extremely low, and high purity SO is produced during absorbent regeneration2Gas. High purity SO by-product of this process2Gas is liquid SO2Excellent raw materials for sulfuric acid, sulfur and other sulfur chemical products.

When the flue gas containsSO2The concentration is low, and the direct production of sulfuric acid cannot be self-heat balance, nor can it reach water balance. In order to achieve the purpose of reducing investment, reducing operating costs, and reducing pollutant emissions, the more reasonable method is: using the combination of ionic liquid desulfurization and acid production, using the split method to part of the flue gas through the one-turn-one-suction process to produce sulfuric acid, the tail gas produced by the sulfuric acid plant enters the ionic liquid desulfurization plant together with the flue gas, desorption of ionic liquid deviceSO2Then return to the sulfuric acid plant to produce sulfuric acid.

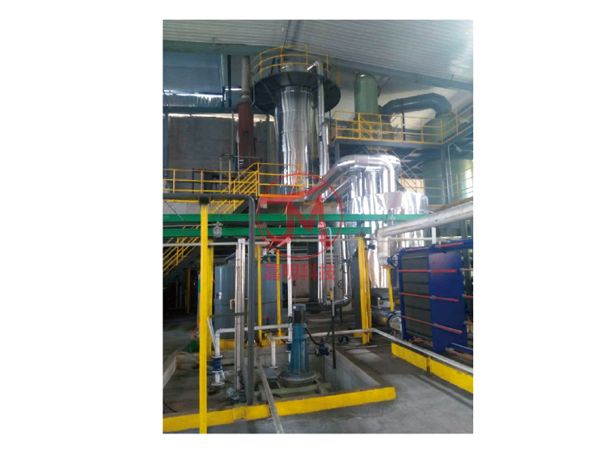

Process flow

After the sulfur-containing flue gas is washed by dynamic wave and defogged by electric demister, part of it enters the desulfurization process, enters the desulfurization absorption tower together with the acid-making tail gas, and is in countercurrent contact with the semi-lean liquid entering from the middle of the desulfurization tower and the lean liquid entering from the upper part,SO2be absorbed. The flue gas after desulfurization is led out from the top of the absorption tower and sent to the chimney for venting.

The ionic liquid that has absorbed sulfur dioxide is called rich liquid, and the temperature of the absorption liquid coming out of the bottom of the absorption zone of the absorption tower is48℃, pressurized by the rich liquid pump, heated by the rich and poor liquid heat exchanger, entered the upper part of the regeneration tower, heated by the reboiler regeneration.

After the solution from the bottom of the regeneration tower is heat exchanged by the rich and poor liquid heat exchanger and cooled by the lean liquid cooler, most of it enters the absorption tower for absorption.SO2, A small part is sent to the solution purification device to remove dust and thermally stable salts in the solution.

The water vapor and sulfur dioxide gas from the top of the high regeneration tower are cooled to about40℃, into the gas-liquid separator, after pressure adjustment, sent to the acid system.

desorption of high puritySO2The gas is replenished to part of the flue gas after scrubbing and demisting by the electric demister, so thatSO2concentration increased6~8%After drying by the drying tower, the water content drops0.1g/nm3Next, enter the main fan. After a conversion of the gas, into a suction tower, the absorption of whichSO3After the flue gas is defogged by the fiber defogger at the top of the tower, it returns to the ionic liquid desulfurization system.

After defogging by the fiber demister of the drying tower, the flue gas from the tower enters the main fan to boost the pressure, and then enters the converter after passing through the heat exchanger. After one conversion, the conversion rate reaches about95%After heat exchange, it enters the absorption tower.

Key words:

8. Ionic liquid desulfurization technology

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.