10. Sulfur-burning sulphuric acid technology

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Sulfur-burning sulphuric acid generally consists of raw material section, sulfur melting section, sulfur burning conversion section, dry suction section, finished product section and tail suction section.

1Raw material and sulfur melting section

The solid sulfur from the raw material section is sent to the rapid sulfur melting tank by the loader and belt conveyor for melting, the molten liquid sulfur flows from the overflow port to the combined filter tank, is sent to the liquid sulfur filter by the filter pump for filtration, then flows into the intermediate sulfur tank, and then is pumped into the liquid sulfur storage tank by the intermediate tank. Before filtration, a certain amount of filter aid should be put into the molten liquid sulfur in the filter precoating tank, and the molten liquid sulfur should be mixed evenly under the action of the stirrer, and the liquid sulfur should be pumped to the liquid sulfur filter after precoating, so that the surface of the filter leaf is covered by the filter aid, and the formal filtration should be started after the filter aid operation is completed. The filtered refined liquid sulfur is sent to the refined sulfur storage tank for storage. During production, liquid sulfur flows from the refined sulfur storage tank to the refined sulfur underground tank and is pumped to the sulfur incinerator for combustion.

The rapid sulfur melting tank, filter tank, filter aid tank and intermediate tank are of concrete integrated structure, arranged underground; each sulfur storage tank and refined sulfur storage tank are equipped with steam heating coil, which is indirectly heated by 0.5~0.6MPa (absolute pressure) saturated steam to melt the sulfur and control the temperature of liquid sulfur at 135 ℃ ~ 145 ℃.

Other equipment such as liquid sulfur filter, sulfur pump and liquid sulfur pipeline, pipe fittings, valves, etc. all adopt steam jacket insulation.

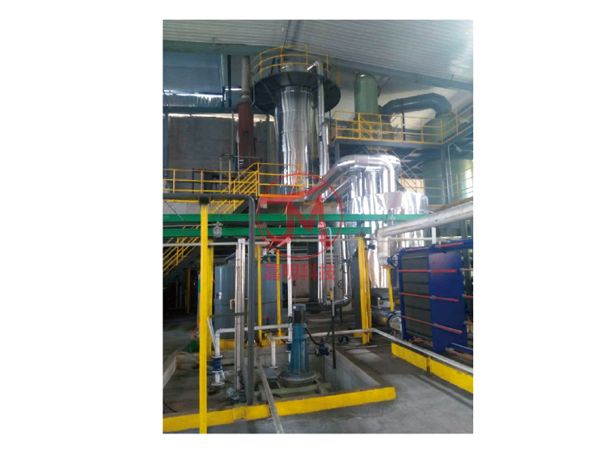

2Sulfur Fen Conversion Section

The liquid sulfur is pressurized by the sulfur pump and sprayed into the sulfur incinerator through the sulfur gun. The air required for sulfur combustion is filtered by an air filter, pressurized by an air blower, dried by a drying tower, and then sent to the sulfur incinerator. The air in the drying tower is dried with 98% sulfuric acid to make the moisture in the air of the tower ≤ 0.1g/Nm3. Dry air is mixed with sulfur in the sulfur incinerator to generate furnace gas containing 10% SO2 and enters the fire tube waste heat boiler for cooling, and the temperature drops from about 1000 ℃ to 420 ℃ and enters the converter.

In order to adjust the gas inlet temperature of each catalyst layer, necessary secondary lines and valves are provided.

A start-up ammonia desulfurization system is arranged behind the secondary suction tower to absorb the SO2 tail gas that has not been completely converted during start-up.

3Dry suction section

Moist air through the air filter to remove dust, into the drying tower. In the drying tower, 98% sulfuric acid is used to absorb the moisture in the air, the acid mist is removed by the wire mesh mist eliminator, and the air blower is sent to the sulfur incinerator for combustion with sulfur.

Spray 98% concentrated sulfuric acid in the drying tower, absorb the moisture in the air and discharge it from the bottom of the tower to the concentrated acid circulating tank. The pump tank chamber is equipped with a dry acid circulating pump and a suction acid circulating pump, which are respectively sent to the corresponding acid cooler and dry suction tower after the acid concentration is adjusted by the water adding device. The secondary suction acid is equipped with an acid circulating tank separately, and the concentrated acid pump is installed on the secondary suction acid circulating tank to regulate 98% H2SO4 by adding water, 98% H2SO4 generated after SO3 absorption is overflowed to the dry suction circulation tank.

The acid cooling circulation system is basically set as follows: tank → pump → acid cooler → tower → tank.

The extra 98% acid is the finished acid. The finished acid is led out from the dry acid outlet, flows into the underground tank through the finished acid cooler and electronic flowmeter, and is sent to the sulfuric acid storage tank or loading tank in the finished product section.

The fan is located in front of the drying tower, which is beneficial to protect the fan from corrosion and ensure the long-term stable and reliable operation of the system.

4Finished product section

The 98% finished sulfuric acid sent from the finished acid cooler is sent to the sulfuric acid storage tank for storage.The mother acid for driving is sent to the concentrated acid circulation tank by the sulfuric acid storage tank by the acid supply pump.

5Tail Suction Section

The tail gas is absorbed by dilute ammonia water. Hydrogen peroxide absorption can also be used as needed. Ammonia desulfurization technology has the advantages of high desulfurization rate, by-product ammonium sulfate fertilizer, simple system, saving floor space, etc. From an economic and technical point of view, the by-products of ammonia desulfurization are ammonium sulfate and ammonium sulfoxide, which are nitrogen-containing and sulfur-containing fertilizers. It can be used alone or together with other nutrients to make compound fertilizers.

After desulfurization and washing, the comprehensive desulfurization efficiency can reach more than 90%, the sulfur dioxide at the tail gas outlet is less than 100mg/Nm3, and the ammonia content is less than 5 mg/Nm3.

Key words:

10. Sulfur-burning sulphuric acid technology

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.