The sulfur foam produced in the coking industry is complex in composition and treatment process. Yangzhou Jiaming Environmental Protection Technology Co., Ltd. has a complete set of salt extraction and acid production technologies for recovering and treating sulfur foam, which recycles all useful elements such as sulfur and nitrogen in sulfur foam, turns sulfur into industrial sulfuric acid, and nitrogen into single industrial ammonium sulfate, thus obtaining industrial sulfuric acid and ammonium sulfate products.

At present, the main processes for the production of sulfuric acid from desulfurization waste liquid in China are wet and dry, and the two processes are different, the main difference is that the pretreatment process of desulfurization waste liquid and the incineration method of the incinerator are different, and the subsequent purification, dry absorption and conversion processes are basically similar, as follows:

1. Wet process flow

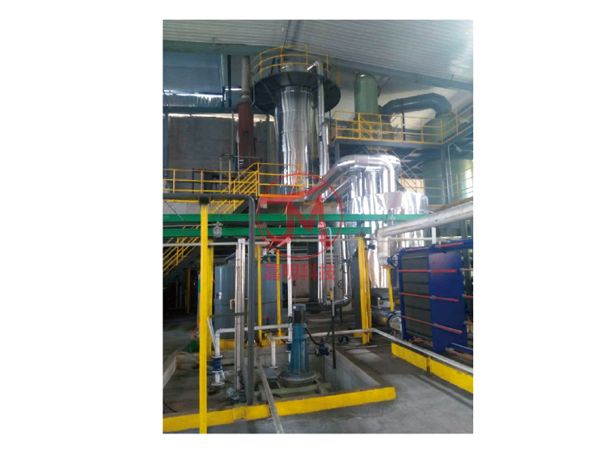

The sulfur foam produced by the regeneration tower of HPF desulfurization device from coke oven gas purification enters the sulfur foam collection tank and is sent to the super centrifuge through the feed pump, the separated sulfur cake is collected in the slurry tank, and the filtrate is collected into the filtrate tank. In order to prevent the accumulation of salts such as ammonium thiosulfate and ammonium thiocyanate in the HPF desulfurization unit, the desulfurization waste liquid to be treated in the original desulfurization unit is also sent to the filtrate tank and sent to the concentration system for concentration through the filtrate pump.

The concentration system consists of a concentration tower, a concentrated liquid circulating pump and a concentrated liquid heater, which is a forced circulation and external heating device. The filtrate in the filtrate tank is directly added to the circulating pipeline before the concentrate heater. After being heated by the concentrate heater, the filtrate enters the concentration tower for evaporation, and the steam at the top of the concentration tower enters the condenser. The concentrated liquid at the bottom of the tower is pressurized and recycled by the circulating pump. The surplus part is sent to the slurry tank by the liquid level control valve to mix with the sulfur cake, and then sent to the sulfur slurry storage tank by the slurry pump, high temperature flue gas containing sulfur dioxide is obtained. After high temperature flue gas is purified and washed, concentrated sulfuric acid is dried, SO2 is converted into SO3 under the action of catalyst, and 98% industrial sulfuric acid is obtained after SO3 is absorbed by absorption tower.

2. Dry process flow

The main task of the raw material pretreatment process is to dry and solidify the desulfurization waste liquid and sulfur foam produced by the desulfurization unit after pretreatment, and the solid crude sulfur is used as the production raw material of the acid plant.

Desulfurization waste liquid and sulfur foam produced by the desulfurization device are sent to the sulfur foam tank through a pipeline, and are sent to a microporous filter through a foam pump. After filtration, a concentrated slurry (containing about 50% water) is obtained. The clear liquid produced by the filter is partially evaporated and concentrated to obtain a concentrated liquid (containing about 50% water), and the remaining clear liquid is returned to the desulfurization system. Concentrated slurry and concentrate into the buffer tank for further treatment (water content of about 50%), the feed pump to the dryer.

The dryer adopts a two-stage series drying form, and uses low-pressure steam to indirectly heat the slurry. The primary dryer uses steam at about 150 ℃ to dry the slurry with water content of about 50% to about 20%. The front section of the secondary dryer uses steam at about 120 ℃ to dry the slurry to dry powder with water content ≤ 2%, and the rear section uses cooling water at about 30 ℃ to cool the dried material loose for convenient transportation and crushing, and the temperature of the discharged powder is ≤ 40 ℃. Therefore, the water in the concentrated slurry is heated and evaporated, and the solid matter is dried, solidified and cooled to become a solid crude sulfur product. Crude sulfur is directly transported to the hopper in front of the furnace by a pipe chain machine for high-temperature incineration to obtain high-temperature flue gas containing sulfur dioxide. After the high-temperature flue gas is purified and washed and dried by concentrated sulfuric acid, SO2 is converted into SO3 under the action of catalyst, and 98% industrial sulfuric acid is obtained after SO3 is absorbed by an absorption tower.