3. Hydrogen sulfide acid making technology

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Hydrogen sulfide (H2S) is a companion product in the process of one-time energy utilization such as coal, natural gas and oil, and is generally used in natural gas purification, petroleum refining, coal gasification and coking.H2Sproduce.H2SIs a colorless rotten egg smell of highly toxic gases, is a strong neurotoxin, the mucous membrane has a strong stimulating effect.

At present, there are two main processes for making acid from hydrogen sulfide: dry process and wet process. The dry process of hydrogen sulfide acid production is similar to the pyrite acid production process, that is, the high-temperature furnace gas produced by the incineration of acid gas containing hydrogen sulfide is first pickled and purified and dried after recovering high-temperature waste heat in a waste heat boiler, and then the traditional two-turn and two-absorption process is carried out to generate sulfuric acid. In the wet process, the high-temperature furnace gas produced by the incineration of hydrogen sulfide acid gas enters the direct converter after recovering high-temperature waste heat in the waste heat boiler, and sulfur dioxide is catalytically oxidized to sulfur trioxide in the presence of water vapor, and sulfur trioxide and water vapor are directly condensed into sulfuric acid in the condenser.

H2S Dry sulfuric acid

Hydrogen Sulfide Wet Production of Sulfuric Acid During Combustion of Hydrogen SulfideSO2After entering the wet conversion, condensed into acid, which on the one hand requires the use of a wet catalyst, on the other hand, due to the high moisture content in the gas phase (greater5%), making the dew point high (240℃ above) is easy to cause corrosion to carbon steel equipment, so there is a dry acid.

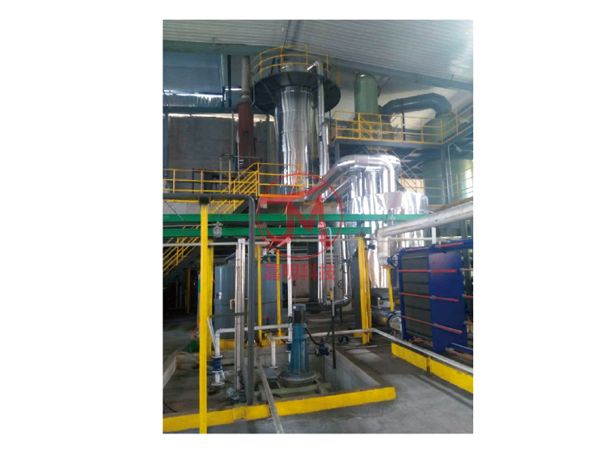

Hydrogen sulfide acid production adopts dry process, similar to the pyrite acid production process, that is, the high-temperature furnace gas produced by the incineration of acid gas containing hydrogen sulfide is first pickled and purified and dried after recovering high-temperature waste heat in a waste heat boiler, and then sulfuric acid is generated by traditional two turns and two absorption. The hydrogen sulfide acid plant of dry process is mainly composed of oxygen sulfide incineration and purification, conversion, drying, absorption and other processes, as shown in the figure below.

Typical Dry Acid Process Flow

At the incinerator outlet950The furnace gas at about ℃ is cooled by heat exchange of the waste heat boiler350℃, into the purification process, the gas after adiabatic humidification cooling into the washing tower, further cooling and heat removal, and part of the acid mist, after entering the two-stage electric demister to remove acid mist, the gas temperature of the electric demister is less40℃ into the drying tower,93%Sulfuric acid absorbs the moisture in the gas, and the moisture content in the furnace gas from the drying tower is less0.1g/m3, the acid mist is less0.005g/m3, enterSO2The main fan enters the conversion system after boosting, and after two conversions and two absorptions, the tail gas is emptied after being treated by the desulfurization tower.

H2Swet sulfuric acid

Wet acid mainly includesH2Sburning,SO2Oxidation and sulfuric acid vapor condensation in three stages.

Sour gas and hot air are sent to the sour gas combustion furnace for combustion reaction, and the combustion temperature of the sour gas in the combustion furnace is about1050C. The hot process gas after combustion enters the waste heat boiler directly through the combustion furnace, and the temperature of the cooled process gas is about440℃, recovered heat production5.5MPagof saturated steam.

The hot process gas is cooled by the waste heat boiler and mixed with high temperature air.SO2reactor, under the action of wet sulfuric acid catalyst,SO2catalytic oxidation conversionSO3. Under high temperature conditions, someSO3The hydration reaction will generateH2SO4The steam enters the sulfuric acid steam condenser to condense the sulfuric acid steam into sulfuric acid.

The tail gas from the sulfuric acid vapor condenser enters the acid mist trap to capture the sulfuric acid aerosol, which is mixed with hot air and sent to the chimney.

Wet acid one turn one coagulation process see below.

One-to-one coagulation process flow for wet acid production

Key words:

3. Hydrogen sulfide acid making technology

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.