2. Mineral acid technology

The complete set of mineral acid production plant refers to the boiling roasting of pyrite acid production, flue gas purification, acid production, tail gas desulfurization, waste acid wastewater and other links as the basis, covering pyrite acid production, refined gold ore acid production, zinc gold ore acid production, manganese ore acid production and other mineral acid production system. A single set of system supporting 12~400000 tons/year acid plant of different sizes.

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Mineral acid complete sets of technology refers to the boiling roasting of pyrite acid, flue gas purification, acid, tail gas desulfurization, waste acid wastewater and other links as the basis, covering pyrite acid, gold concentrate acid, zinc concentrate acid, manganese ore acid and other mineral acid system technology. A single set of system supporting 12~400000 tons/year acid of different scales.

Pyrite acid is generally composed of raw materials, roasting, purification, conversion, dry suction, tail suction, finished products and other processes.

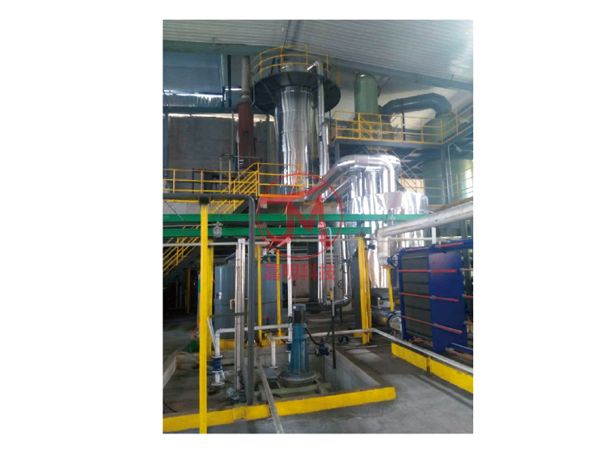

A typical 400kt/a pyrite sulphuric acid process flow is shown in the following figure.

Typical 400kt/a pyrite sulphuric acid production process

Raw material process: the qualified sulfur fine sand transported from the selection plant enters the raw material warehouse first, and then is fed into the storage hopper by the bridge grab machine. after the two-stage steam drying process, the moisture content drops to about 8%, and is transported to the feeding hopper of the feeding room through the belt conveyor.

Roasting process: sulfur concentrate raw materials are fed from the feeding hopper through the feeding belt, metering belt, transfer belt and star feeder into the two feeding mouth of the boiling furnace respectively, and are mixed with air from the air blower in the boiling furnace for boiling roasting. The high-temperature flue gas with S02 ~ 13.5 and temperature of ~ 950 ℃ produced by roasting is partially recovered by waste heat boiler. After the temperature drops to ~ 350 ℃, it passes through cyclone dust collector and electric dust collector in turn, so that the dust content in the furnace gas drops to ≤ 0.1g/Nm3 and enters the purification section.

The high-temperature slag from the waste heat boiler passes through the air-cooled buried scraper conveyor and enters the submerged cooling drum together with the high-temperature slag from the boiling furnace. The slag dust from the cyclone dust collector and the electrostatic precipitator enters the next submerged cooling and humidifying drum together with the slag from the submerged cooling drum through the rotary valve to continue cooling, and the temperature drops to 70 ℃. The cooled slag is transferred to the slag yard by the belt conveyor and then transported out.

Purification process: the furnace gas from the roasting section enters the dynamic wave scrubber. The dynamic wave scrubber in the purification section uses 10% dilute sulfuric acid to carry out adiabatic humidification and washing on the roasting flue gas. The temperature of the washed furnace gas is reduced from 280-320 ℃ to ~ 67 ℃, and most of the ore dust in the furnace gas is washed into dilute acid. The furnace gas then enters the packing tower for washing, and is further washed with 3% dilute sulfuric acid to remove dust, As, F and other impurities in the furnace gas. The temperature of the furnace gas is reduced to below 40 ℃, and then enters the electric demister for demisting. After purification, the furnace gas goes to the drying tower.

Dry suction process: the purified furnace gas enters the drying tower, and 93% sulfuric acid is sprayed to absorb the water in the purified gas, so that the water in the purified gas is reduced

Conversion process: The process flow of the conversion section adopts 3 1 two conversions, I .e. III, I-IV II heat exchange process. The purified gas from the S02 fan passes through the tubes of the III and I heat exchangers in turn to exchange heat with the high-temperature S03 gas from the third and first sections of the converter. The temperature rises to about 410 ℃ and enters the converter. The converted gas after heat exchange enters the first absorption tower and absorbs S03 in the first and 2. sections. The gas from the first absorption tower exchanges heat with the high-temperature converted gas from the fourth and second sections of the converter through the tubes of the Ⅳ and Ⅱ heat exchangers in turn. After the temperature rises to 425 ℃, the gas enters the fourth section of the converter. After the conversion through the fourth section of the converter, the gas exchanges heat through the Ⅱ and Ⅳ heat exchangers respectively, and the temperature drops to ~ 165 ℃ to enter the second absorption tower. The total conversion rate of the conversion rate of the conversion system can reach 99.8.

The smelting flue gas acid process does not have the raw materials and roasting process of the above-mentioned pyrite acid, and other subsequent processes are similar to pyrite acid, consisting of purification, conversion, dry suction, tail suction, finished products and other processes. According to different metal smelting varieties and smelting process, smelting flue gas acid also has its unique characteristics.

(1) is the gas volume and gas concentration fluctuations are relatively large. The acid process requires stable gas volume and moderate gas concentration. However, smelting flue gas is difficult to meet these requirements. In particular, the current widely used converter flue gas, not only the periodic gas volume and gas concentration changes, but also due to frequent feeding, slag discharge and discharge, resulting in the intermittent phenomenon of stopping the air supply. This brings some difficulties to the acid system.

(2) The concentration of sulfur dioxide is relatively low. In addition to zinc concentrate or copper concentrate using boiling furnace oxidation roasting and copper concentrate flash smelting flue gas concentration can reach 10%-13%, zinc industry ore boiling furnace sulfation roasting gas concentration can reach 8%-9%, the rest of the smelting flue gas gas concentration is relatively low, converter flue gas can theoretically reach 21% in the second cycle, but due to feeding, slag discharge caused by intermittent and a large amount of air leakage in the hood, nor can they be listed as high concentrations of smoke. The flue gas concentration of lead-zinc sintering machine is 4% ~ 6.5; the flue gas of closed blast furnace (copper) is 3% ~ 5%. Secondly, the flue gas concentration of blast furnace, electric furnace and reverberatory furnace is lower.

(3) is the composition of smelting flue gas is more complex in the smelting flue gas, not only contains sulfur dioxide and sulfur trioxide, but also more than the pyrite acid flue gas particle size more fine metal oxide dust. Some of these dust is volatilized in the vapor state, and when the temperature is lowered, it condenses into very fine particles. For example, lead, zinc, antimony, bismuth, cadmium, selenium, tellurium, thallium, arsenic and other impurities. To remove these impurities requires more complex purification methods. In addition, there are gaseous impurities such as hydrogen fluoride, carbon monoxide, carbon dioxide, and a large amount of water vapor, which all bring certain difficulties to acid production. Therefore, the furnace gas purification process requirements are higher.

Key words:

2. Mineral acid technology

Recommend products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.