5. Efficient scrubber

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

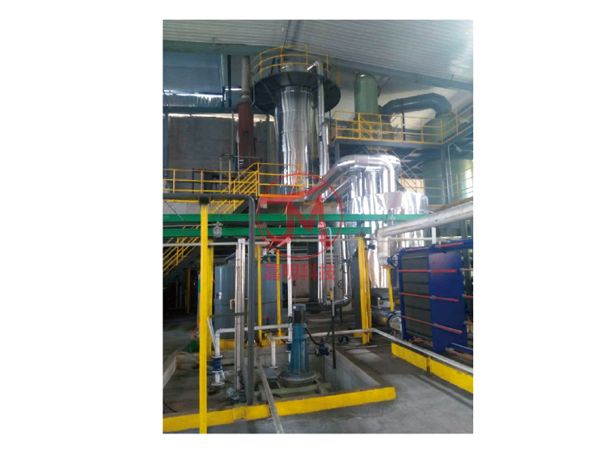

Wet scrubber is a liquid (usually water) as the washing liquid, through the gas-liquid two-phase contact, to achieve the gas-liquid two-phase heat transfer, mass transfer and other processes, to meet the gas purification (dust removal or absorption), cooling, humidification and other requirements. In order to obtain as large a gas-liquid two-phase contact surface as possible and achieve full contact between the gas and liquid two phases, the commonly used wet scrubbers generally adopt the following methods:

(1) Atomize the washing liquid into fine droplets, increase the specific surface area of the liquid phase, and require the atomized droplets to be dispersed in the gas as evenly as possible. Among them, the use of liquid-phase kinetic energy for washing liquid atomization has spray washing tower, Jet scrubber, Centrifugal spray scrubbers, etc.; a typical device that uses the kinetic energy of a high-speed airflow to atomize the scrubbing liquid is a venturi scrubber.

(2) so that the washing liquid forms a very thin liquid film, as the contact surface of the gas-liquid two-phase, such as packed tower, Water film cyclone separator.

(3) The gas is used as the dispersed phase and the washing liquid is used as the continuous phase, I .e. the gas passes through the liquid layer in the form of small bubbles to realize the heat and mass transfer process of the gas-liquid two-phase, such as foam tower and impact scrubber.

20Century70Developed by DuPont in the United States. "Dynamic wave foam scrubber" uses a unique washing method, namely foam washing, which not only uses the energy of the air flow, but also cleverly uses the energy of the liquid flow. The first industrial application device1986It has been widely used in waste acid recovery, calciner, titanium dioxide acidolysis tank, ammonium thiosulfate, oleum, sulfuric acid drum concentrator, pulverized coal boiler, silicon halide,HCland nickel chloride recovery40A number of different production occasions, involving metallurgy, chemical industry, building materials, food and other industries.

The high-efficiency scrubber adopts a unique washing method. Its working principle is: the gas enters the washing tube at high speed from top to bottom, and the washing liquid is sprayed into the airflow from bottom to top through a nozzle with a special structure. The gas-liquid two phases collide in high-speed reverse direction. When the momentum of the gas-liquid two phases reaches equilibrium, a highly turbulent foam zone is formed. The contact surface area is large, and these contact surfaces are continuously updated rapidly, to achieve efficient washing effect.

The equipment consists of a washing tube, The nozzle and the washing liquid storage tank are composed of three basic parts. Its performance characteristics: (1) High purification efficiency. The purification efficiency of high-efficiency scrubbers is much higher than that of traditional washing equipment such as spray towers and packed towers, especially for the removal of sub-particles, which is more effective.99more than%. (2) The equipment has simple structure, small appearance, convenient and flexible configuration, easy material solution, saving investment and land occupation. (3) Since the liquid injection into the gas is carried out by a large liquid nozzle with holes, the circulating liquid can allow higher solid content without clogging. Due to the high solid content of the circulating liquid, the liquid discharge can be reduced, thereby reducing the load and scale of the sewage treatment device. General traditional washing equipment is difficult to bear3% or more of the solid content of the circulating liquid, while the high-efficiency scrubber can reach20% of the circulating liquid solid content without clogging. Therefore, the high-efficiency scrubber has high reliability, is not easy to damage, simple operation and maintenance, and long operation cycle. (4) Flexible configuration and wide application range. Properly designed, high-efficiency scrubbers can be used in almost any gas purification process. For example, its cooling effect is quite good and can be used to treat various high-temperature gases. It is not easy to block, the dust content in the gas is almost unlimited, and the allowable dust content in the circulating liquid is also extremely high. If the process itself allows, the amount of waste liquid extracted can be greatly reduced, making the treatment of waste liquid easier. The appearance is small, the strength and sealing problems are easy to solve, and the working process is not affected by pressure, so it can be operated at any pressure. The area of the foam area is very large, there is a wide range of gas adaptability, can adapt50%~ 100% of the gas volume without reducing the washing efficiency. Basically meet the needs of most processes.

Key words:

5. Efficient scrubber

Next

Next

Recommended Products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.