1. Waste acid cracking furnace

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

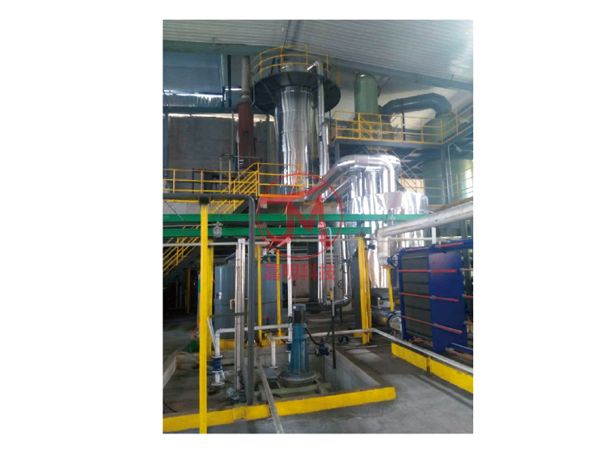

waste acid cracking furnace

Waste acid cracking furnace is a kind of equipment used to treat waste acid, its main function is to decompose the organic matter in waste acid into useful chemicals, is the key equipment of waste acid regeneration device, waste acid cracking furnace mainly includes cracking furnace cylinder, burner, waste acid nozzle, lining and heat exchanger and other components.

The design of the waste acid cracking furnace needs to take into account the type and composition of the waste acid. Different types of waste acids have different chemical compositions and physical properties, so it is necessary to select the appropriate cracking furnace type and process parameters according to the characteristics of waste acids. Parameters such as temperature, pressure and reaction time of the cleavage reaction need to be taken into account. The selection of these parameters needs to be determined according to the composition of the waste acid and the requirements of the cracking products.

The cracking furnace barrel mainly includes the shell, the insulation pouring layer, the refractory lining, the furnace head end plate is provided with waste sulfuric acid spray gun installation hole, gas.-Air burner installation holes, upper opening retaining wall and lower opening retaining wall are alternately arranged in the furnace, flame monitor installation holes and mirror installation holes are arranged on the furnace cylinder, and the furnace gas outlet is arranged on the cracking furnace tail, the end plate of the cracking furnace tail or the cylinder.

The burner is the core component of the waste acid cracking furnace, and its working environment is relatively harsh.H2Sof acid gas, and combustion air up 500 ℃, while being exposed to high temperatures and the presence of sulfuric acid mist,SO2,CO2,H2OIn the environment of other gases, it is easy to cause corrosion of the burner, so it is different from the regular burner, and its shell material is adopted.06Cr19Ni10, the material of the burner is adopted06Cr25Ni20In order to achieve the purpose of long-term stable operation. The basic requirement for burner operation is that the flame is straight and strong, And with strong mixing and stirring function. In addition, from the safety point of view of the operation of the furnace, the burner must be equipped with two sets of ultraviolet flame detection system, If one set of fire detectors detects that there is no flame in the furnace, it will give an alarm. If two sets of fire detectors detect that there is no flame, the fuel and gas source will be interlocked and cut off immediately.

The waste acid nozzle is also one of the core components of the waste acid cracking furnace. The atomization effect directly affects the cracking degree of waste sulfuric acid. If the atomization effect is not good, the undecomposed sulfuric acid will cause serious corrosion to the cracking furnace shell, and at the same time, elemental sulfur may be decomposed, which will block the downstream equipment and cause the device to be forced to stop. Therefore, higher requirements are put forward for the structure of the waste acid nozzle to meet the requirements of complete atomization of waste acid. Considering the strong corrosion of waste acid nozzle by waste sulfuric acid and the influence of high temperature, waste acid nozzle06Cr20Ni30Mo2Cu3Material of iron-nickel alloy stainless steel, this material in the sulfuric acid environment has an extraordinary resistance to acid corrosion performance.

Lining material: under normal conditions, the furnace operating temperature is1 000~1 100℃, but in the case of improper air volume control or unstable air volume, the furnace temperature may reach1 400C, so the lining material must be selected to meet the operating conditions of the refractory material, but also requires the lining material has a stable thermal conductivity, acid resistance and good thermal shock stability. Qualitative.

Lining structure: At present, there are two kinds of structures of domestic waste acid cracking furnace lining. One is“Lightweight heat-insulating castable+High-aluminum plastic fire-facing surface)”Composite lining, lining anchorage adopts corundum anchor brick and anchor nail combined structure. This kind of structure has good integrity, good thermal shock resistance, low investment and simple construction, but the construction and oven requirements are relatively high, requiring continuity during construction. The other is“Lightweight heat-insulating castable+Corundum refractory brick (facing surface)”Composite, this structure has good high temperature resistance and corrosion resistance, but the cost is high, and the brick structure is also limited by the diameter of the furnace. If the diameter is large, the connectivity of the overall structure of the brick is reduced, and the upper part is under strong thermal shock. Refractory bricks are easy to fall off.

The performance of acid gas burner of cracking furnace, the atomization effect of waste acid nozzle, the selection of material of furnace components and the rationality of lining material and structure directly affect the normal production of the device.

Key words:

1. Waste acid cracking furnace

Pre

Pre

Recommended Products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.