6. Suction tower

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Sulfuric acid desorption tower, also known as degasser, is mainly used in the following three situations: (12) Used to remove sulfur dioxide dissolved in acid in the production of refined sulfuric acid; (22) Set up a suction tower to remove concentrated sulfuric acid from dry suction process and reduce the flue gas at the outlet of the absorption tower.SO2concentration and in the finished acidSO2content; (32) Removal of acidic wastewater from purification processSO2Gas.

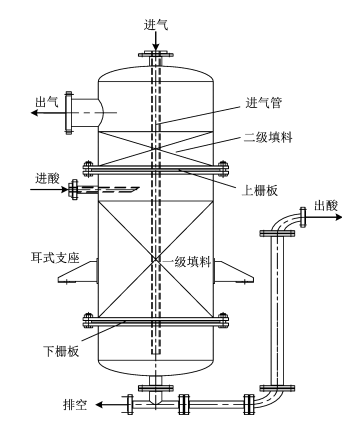

The suction tower usually uses a packed tower to use the air purified by the concentrated sulfuric acid drying tower. The liquid flows from top to bottom and the gas goes from bottom to top, so that the two media contact each other to achieve the effects of heat transfer, suction and purification. The suction tower is generally composed of tower body, air pipe, acid pipe, packing, grid plate, etc. The structure is shown in the figure below.

A liquid distributor and a spray head are installed above the packing. Acid enters from the upper part of the suction tower, is sprayed through the spray head, and is evenly sprayed on the top of the tower through the liquid distributor, and is discharged from the bottom of the tower after passing through the packing layer;SO2The air is introduced from the bottom of the suction tower by using the negative pressure formed in the pipeline. In the suction tower, the air is in countercurrent contact with the acid. Due to the blocking effect of the filler, the acid flow from top to bottom is dispersed into many small strands or drops, and the gas-liquid two-phase mass transfer on the surface of the liquid film, so that the dissolved acidSO2The gas is released.

Key words:

6. Suction tower

Recommended Products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.