2. Sulfur combustion furnace

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

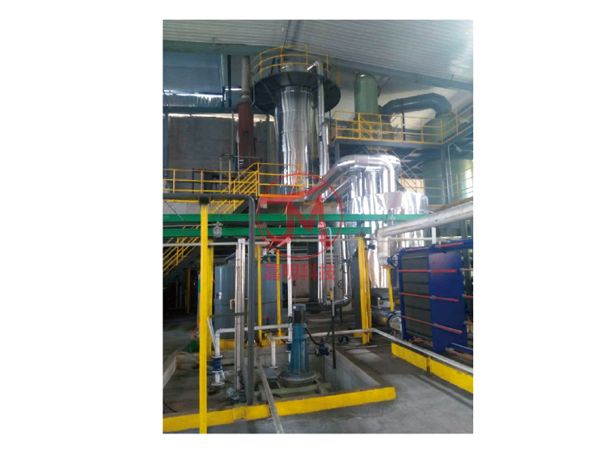

Sulfur combustion furnace, also known as sulfur incinerator, is the key equipment in the sulfur-burning acid process.

The sulfur incinerator is generally a horizontal structure with steel cylinder lined with refractory bricks and thermal insulation bricks. Multiple retaining walls and secondary air inlets are set in the furnace to enhance the mixing of air and liquid sulfur atomized particles and ensure the complete combustion of liquid sulfur in the furnace.

At present, there are mainly two types of sulfur incinerators in China, one is a cylindrical horizontal sulfur incinerator, each sulfur gun at the furnace head is equipped with an air swirl device; the other is an enlarged horizontal sulfur incinerator, the air inlet adopts a double spiral structure air inlet device, the furnace head is equipped with a large volute swirl device, and several sulfur guns are placed in the middle of the swirl device. Under the premise of ensuring the full combustion of liquid sulfur, the volumetric thermal intensity of the sulfur incinerator is improved.

The steel shell of sulfur incinerator is mainly composed of cylinder, reinforcing ring, manhole and flat head at both ends. The cylinder material is adoptedQ345A, adoptQ235BSteel plate material welded to strengthen the ring. The pipe orifice mainly includes primary air inlet, secondary air inlet, gas outlet, burner installation port, mirror cooling air inlet, automatic temperature measuring port, mirror and liquid sulfur inlet. In order to prevent rainwater from directly spraying the high-temperature outer wall of the furnace body and radiating gas to the environment, a rain cover is installed in the upper part of the sulfur incinerator. In order to facilitate maintenance, a manhole is set at one end of the sulfur incinerator.

Refractory masonry is the main structure of sulfur incinerator, equipment is generally not set up external insulation, furnace insulation is mainly composed of internal high alumina refractory brick and high alumina insulation refractory brick.

The arch retaining wall is set in the sulfur incinerator to strengthen the mixing state of sulfur and air, enhance the turbulence degree of furnace gas, increase the flow speed of furnace gas, improve the distribution of furnace gas in the sulfur incinerator and extend the residence time, which can promote the full combustion of sulfur in the furnace.

Under the operating condition of masonry, due to the change of temperature, the masonry will shrink and expand. Because the expansion amount is not completely consistent with the cement shrinkage or the residual deformation of the brick, if the masonry is not provided with expansion joints, the internal stress generated will deform the furnace, causing the masonry to arch and crush. The setting principle of expansion joint is: it can not become the gap of furnace gas circulation, can not weaken the strength of masonry, at the same time, it should be evenly separated.

The cyclone device is set to ensure the full mixing of air and sulfur, and at the same time prevent the accumulation of fine char ash in the lower part of the furnace near the gas inlet due to the large dead angle of the air flow in the furnace, which can reduce the utilization rate of the furnace, strengthen the early mixing process, and make the gas rotate violently in the furnace. The swirl device generally divides the airflow entering the sulfur incinerator into two parts. One part of the airflow enters the cylinder through the tangential inlet nozzle and rotates through the small cone cylinder, and the other part of the airflow passes through the gap between the inner and outer cones. Several spiral blades are installed in the gap, and the airflow moves spirally along each channel after entering.

Key words:

2. Sulfur combustion furnace

Recommended Products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.