15. Flue gas desulfurization tower

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

Flue gas desulfurization tower is used to remove sulfur dioxide in the gas equipment. Boiler exhaust, sintering flue gas, sulfur-containing waste combustion flue gas, etc. all contain a certain amount of sulfur dioxide. Sulfur dioxide is the culprit for acid rain and environmental pollution. Therefore, the flue gas containing sulfur dioxide is passed through a flue gas desulfurization tower and passed through different media (such as lye, lime powder, activated carbon and organic amines, etc.) to convert sulfur dioxide into salts or be adsorbed, so that the flue gas can be treated and eliminate environmental pollution.

Wet desulfurization absorption tower has many kinds of structure, according to different gas-liquid contact mode, desulfurization tower can be divided into spray tower, packing tower, bubble tower and liquid column absorption tower, etc., in which the spray tower has the advantages of high efficiency, low resistance and high availability.

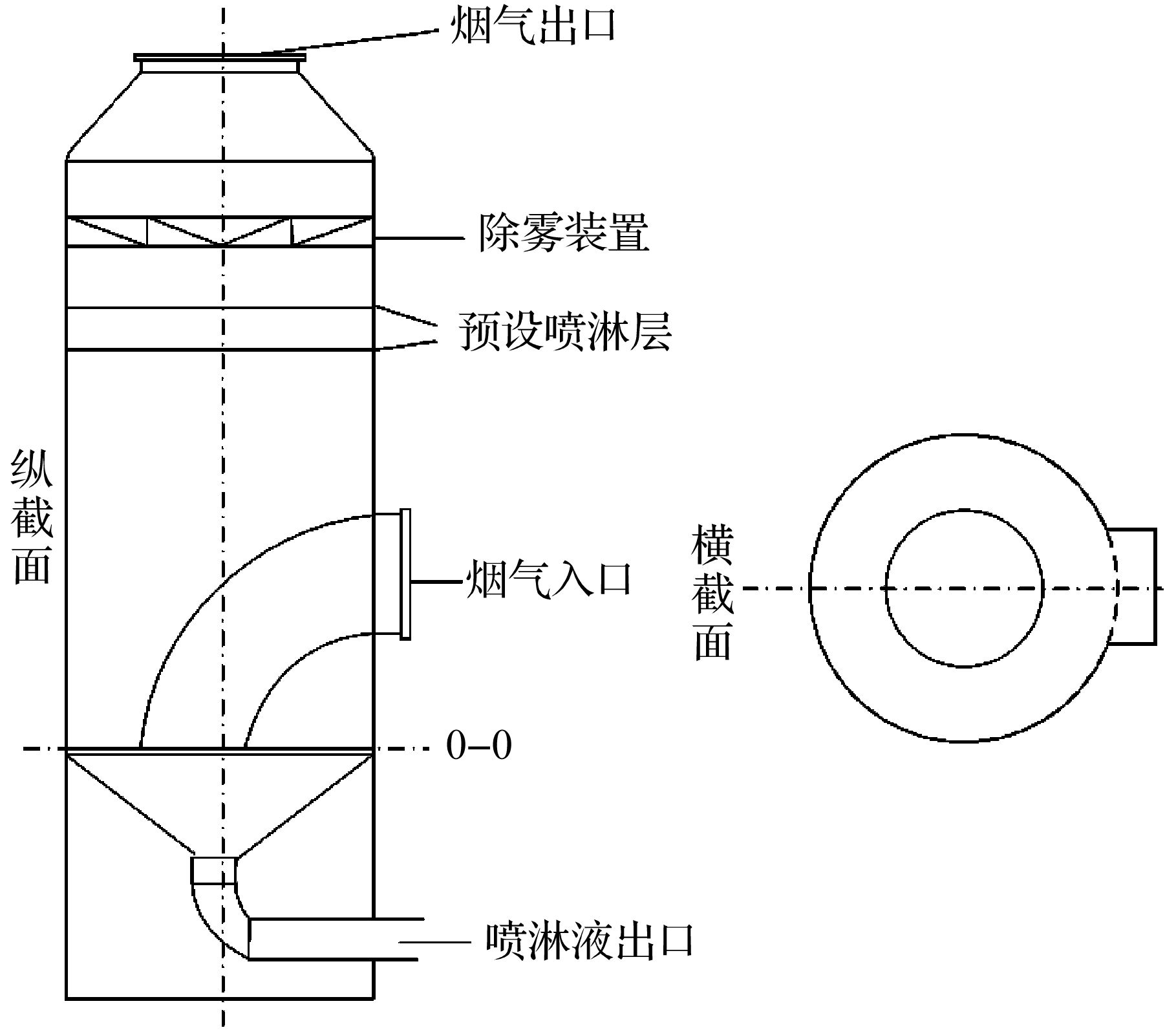

Spray tower is a commonly used equipment in gas-liquid reaction engineering. Lime slurry (or alkali liquor, etc.) is pumped to spray nozzles arranged at different heights in the tower. The nozzle is made of wear-resistant material. Slurry (or lye, etc.) is sprayed downward from the nozzle to form dispersed small droplets and fall downward. At the same time, the flue gas flows upward in countercurrent, during which gas and liquid fully contact and wash sulfur dioxide. Technically, the nozzle is required to reduce the pressure loss as much as possible under the condition of meeting the atomization fineness. At the same time, the sprayed mist can cover the entire absorption tower section to achieve the stability and uniformity of absorption. The oxidation tank is generally arranged at the bottom of the tower, and a special oxidation fan is used to blow air inside, while the mist eliminator is arranged in front of the flue gas outlet.

In the development process of flue gas desulfurization technology, the spray tower is the earliest desulfurization reaction device, its advantage is that it can form a larger gas-liquid contact area, the system of liquid and gas is relatively small. In order to ensure a good atomization effect, the slurry (or lye, etc.) is sprayed to form uniform and tiny droplets. The circulating pump must provide sufficient pressure, and the size of the desulfurizer particles in the slurry (or lye, etc.) cannot be too large, otherwise the nozzle Easy to be blocked.

The equipment contained in the flue gas desulfurization tower mainly includes a stirrer, an oxidation duct, a spray pipe, a demister, etc., and some designs also include a deflector or a uniform distribution plate, etc. The agitator is located at the bottom of the desulfurization tower, which mainly plays the role of slurry disturbance, in order to prevent the precipitation of gypsum and other particles. The function of the oxidation air pipe is mainly to inject air into the slurry pool in the tower to oxidize sulfite into sulfate, and its supporting equipment is the oxidation fan. The function of the spray pipe is that the slurry is pumped above the page of the slurry pool of the desulfurization tower through the nozzle for atomization and distribution, thus absorbing the flue gasSO2Gas; the main function of the demister is to remove the liquid droplets carried in the flue gas, that is, the role of water removal.

Structure Diagram of Desulfurization Tower

It is necessary to select the appropriate desulfurization tower and desulfurization agent according to the specific desulfurization process and industrial application scenario, and design and optimization.

Key words:

15. Flue gas desulfurization tower

Recommended Products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.