3. Boiling furnace

We have always been committed to the research and development and promotion of acid and environmental protection technologies. The developed zero-discharge wastewater technology, high-temperature cracking and recovery of refractory waste acid, high-arsenic ore treatment and arsenic recovery, and sulfur downstream product production technology have been widely used in the industry. The promotion and application of these technologies have enabled the project device to meet the strict national emission standards and also achieved the goal of energy saving and consumption reduction.

Classification:

Message

Description

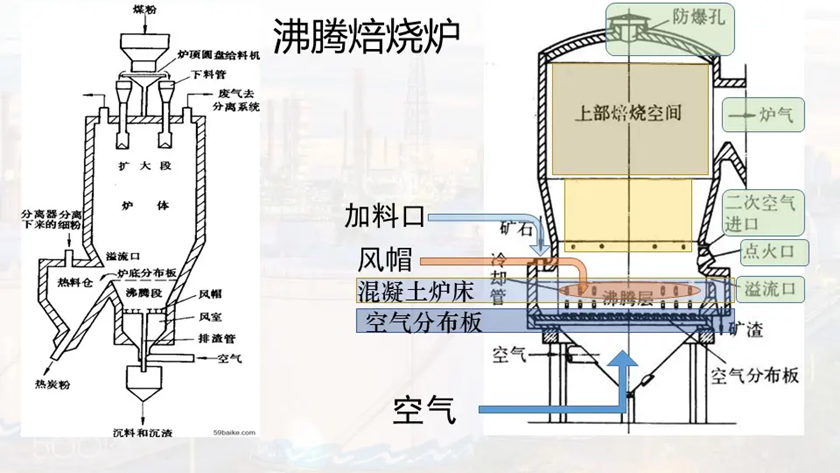

Boiling furnace is one of the core equipment of sulfuric acid industry, also known as boiling roaster, also known as fluidized bed roaster, is a device for roasting sulfide ore with solid fluidization technology. During the roasting process, the reaction heat is released and the gas containing sulfur dioxide is mainly used to make sulfuric acid, and the slag is used as a metallurgical raw material.

The furnace body of the boiling baking furnace is composed of steel shell lined with thermal insulation bricks and then lined with refractory bricks. In order to prevent condensation acid corrosion, steel shell outside the insulation layer. The lowest part of the furnace is the air chamber, which is provided with an air inlet pipe, on which is an air distribution plate. The air distribution plate is a refractory concrete hearth with many air caps with small holes in the side. The central part of the furnace is a cone expanding upward, and the cross-sectional area of the upper baking space is larger than the cross-sectional area of the boiling layer to reduce the blowing of solid particles. The boiling layer is equipped with cooling pipe of waste heat boiler, and the furnace body is also provided with connecting pipes such as feeding port, slag overflow port, furnace gas outlet, secondary air inlet and ignition port. There are explosion-proof holes in the furnace roof.

Boiling furnace is mainly divided into two types: straight tube type furnace and upper expansion type furnace: ① straight tube type furnace. It is mostly used for roasting of non-ferrous metal concentrates, with low roasting intensity, no expansion or slight expansion of the upper part of the furnace, and its appearance is basically cylindrical. ② Upper enlarged furnace. In the early days, it was used to roast crushed lump ore (pyrite mined as raw material for sulfuric acid production, mostly in blocks, which is used to be called lump ore). Later, it was developed for roasting of various flotation ores (including non-ferrous metal flotation concentrates, pyrite-containing tailings produced by by-products during beneficiation, and sulfur concentrates obtained by flotation in order to improve the grade of pyrite. The particle size of these ores is very small), with high roasting intensity.

The boiling process is the same as the particle size of the raw materials in the furnace, the air flow velocity, the roasting intensity, Factors such as bed height and gas distribution are closely related.

Raw material particle size.The boiling of the material layer in the boiling furnace is first related to the condition of the raw material. The critical flow rate of small particles starting to boil is low and easy to fluidization, while the larger particles are fluidized only when the air volume is sufficiently large. The basic relationship between the particle size of the furnace and the particle size of the raw materials is generally coarsened with the increase of the average particle size of the raw materials into the furnace, and coarsened with the increase of the particle size distribution range, so it is very important to control the stability of the raw material particle size in order to obtain a certain range of stable boiling conditions.

Airflow velocity.The main factor that determines that the fixed bed will become a boiling bed is the airflow speed. Under different material layers, how much wind speed can make the material layer start to boil and how much wind speed can make the furnace run normally, The problem of how much air volume and air pressure to the blower in operation is closely related to the critical velocity of the ebullated bed and the fluid resistance of the ebullated bed.

Roasting strength.The roasting intensity of the fluidized bed furnace is an important index to measure the production capacity.

Bed height.The fluidized bed height includes the boiling layer height and the separation space height.

Gas distributor.The gas distribution device is very important to ensure the quality of fluidization, increase gas-solid contact and prevent stagnant materials. The distributor is able to evenly distribute gas, create a good initial fluidization conditions and be able to maintain long-term stability, the most important reason is that it has a certain resistance or pressure drop for the fluid through, only when the resistance It is large enough to overcome the free distribution of unstable gas flow, and it can continue the good initial fluidization conditions for a long time. The pressure drop of the distributor is mainly determined by the opening rate. Under the same other conditions, increasing the pressure drop or reducing the opening rate of the distributor can generally improve its air distribution and stability.

Key words:

3. Boiling furnace

Recommended Products

Get free product quotes

Yangzhou Jiaming Environmental Protection Technology Co., Ltd.

Address: Fangxiang Industrial Park, Hanjiang District, Yangzhou City, Jiangsu Province

Contact: Tang Jiafu13951439212

Contact: Wu Weimin13952058396

E-mail:jmkj88@yeah.net

Scan QR Code

Copyright:Yangzhou Jiaming Environmental Protection Technology Co., Ltd.